ALUMINUM – STRUCTURAL

Xiaomi Auto Technology Co, Ltd

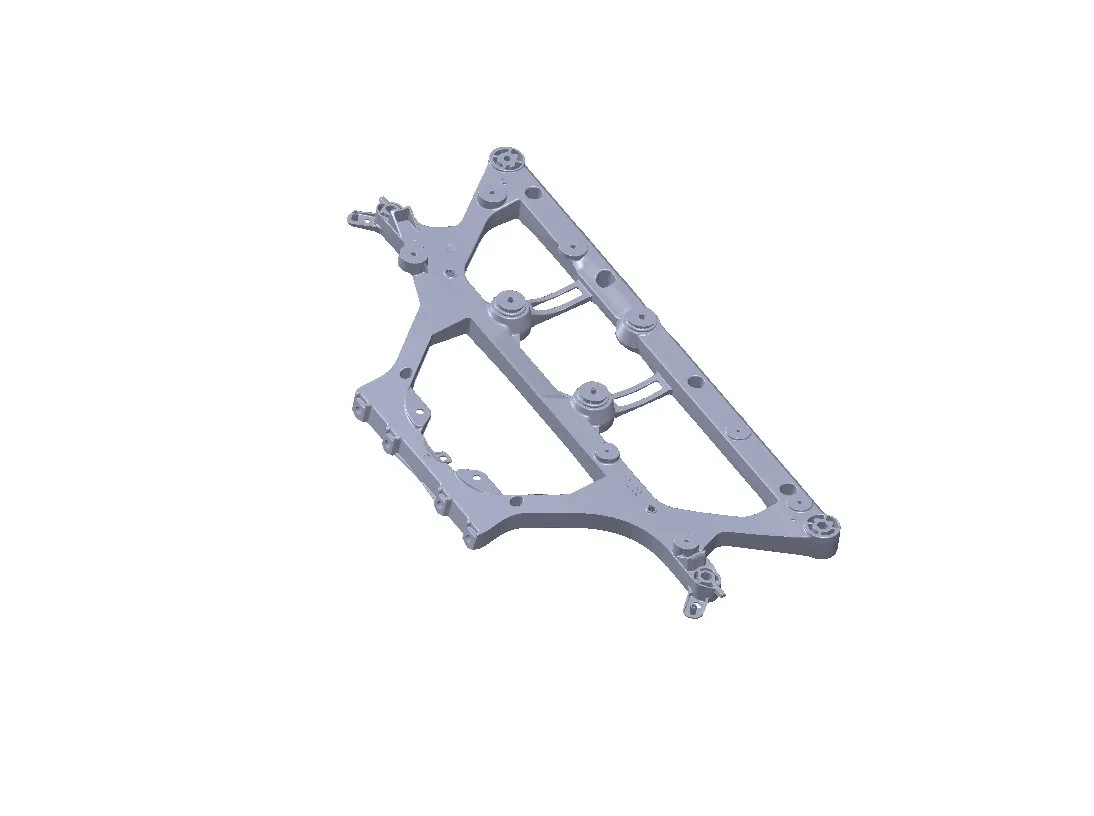

PART: Front Cabin Triangular Beam AssemblyMATERIAL:Alcoa C891FWEIGHT: 11.7 lbs (5.3 kg)END MARKET: AutomotiveCaster Award Nominees: Cui Qiang, Liao Pingwei,

Dai Tailiang (Xiaomi Auto Technology Co, Ltd), Xinyan Yan (Alcoa Corporation), Cheng Shuai (CSMET New Materials Group Co., Ltd), Zhang Lei (KPSNC)

Developed in partnership with Alcoa.-

FUNCTION OF PART

The front cabin triangular beam assembly serves several essential functions:

Connect the left and right front shock absorber tower and front dash panel

Meet the installation and fixing requirements of five major thermal management modules, including the air conditioning compressor, refrigerant module, cooling module, air conditioning box, high-efficiency particulate air filter

-

PREVIOUS PROCESS TO PRODUCE PART

Traditional design methods were used to join more than 20 steel stamping components by welding. In addition, the air-conditioning compressor is mounted to the steel triangular beam via one adapter structure.

-

ADVANTAGES GAINED

The front cabin triangular beam assembly has the following notable characteristics:

Modular and Integrated Design, Modular Assembly Design, Bench Closed-loop Verification Technology, Extra-large Front Trunk Volume, Higher Safety, Higher Rigidity, and New Heat Treatment-free Cast Aluminum Material