ZINC

under 6 oz

Shakespeare Machine Stamping

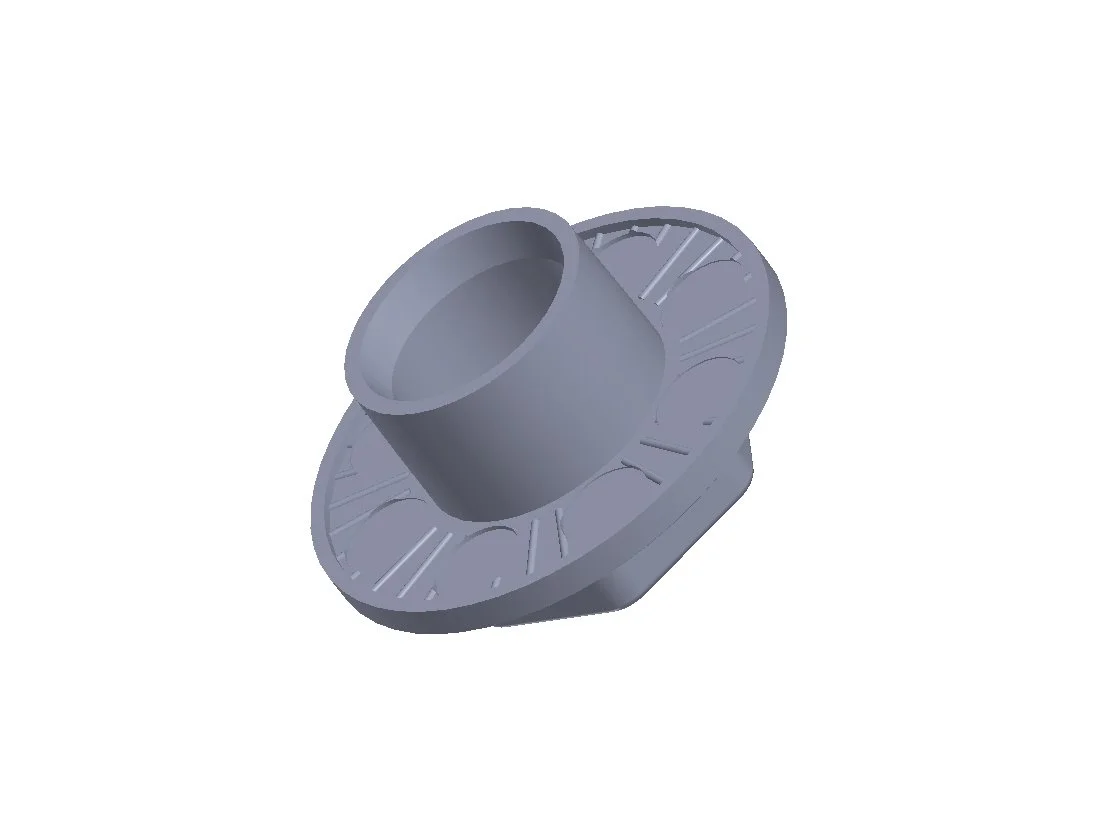

PART: JZ Zinc FlangeMATERIAL: Zamak 3WEIGHT: 1.6 oz (44 g)END MARKET: Power ToolsCaster Award Nominee: James Haarsma-

FUNCTION OF PART

The JZ Zinc Flange is one of a series of Shakespeare’s center hub flanges that function as the center component linking the arbor to the grinding wheel.

-

PREVIOUS PROCESS TO PRODUCE PART

These parts were originally produced on a 6-cavity tool using a conventional zinc die casting machine. The casting undergoes an orbital riveting process, highly deforming the hub around the center arbor of the grinding wheel. This dual requirement of functionality combined with a high-quality surface made this casting process historically difficult to manufacture.

-

ADVANTAGES GAINED

To produce these parts, Shakespeare invested in the newest technology in the zinc industry, including an 80T Frech hot chamber die casting machine, a 2-drop hot runner manifold system, and tooling by Contour Tool uniquely designed for the hot runner system. More cavities: eliminated the casting sprue and allowed for a redesign of the layout to increase cavities from 6 to 10. Shorter cycle time: hot runner technology allowed the cycle time to be reduced to 6.3 seconds per shot. Higher production rates: Faster cycle times and more cavities allow for a production rate of 5,700 parts per hour. Quality improvements: Improvements in surface quality and significant reduction in porosity resulted in a defect rate of zero. Additional work: Shakespear has converted additional tools to the hot runner system based on the success of this part.